The Structure and Characteristics of Precision Roller Chain

- Share

- Issue Time

- Sep 17,2021

Summary

The application of precision roller chain is very wide, suitable for small power transmission, but many people still know little about it.

Roller chain usually refers to the precision roller chain for short pitch transmission. It is the most widely used and the most output. Roller chains are divided into single rows and multiple rows, which are suitable for small power transmission. The followings are the structure and characteristics of the roller chain.

Roller chain composition

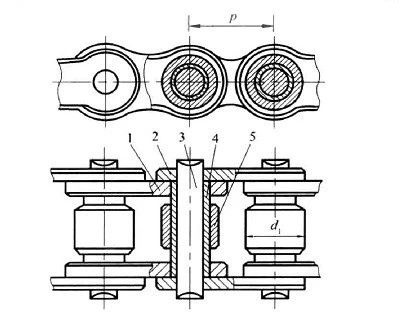

As shown in the figure, the roller chain is composed of inner chain plate 1, outer chain plate 2, pin shaft 3, sleeve 4, and roller 5.

Roller chain structure

The inner chain plate and the sleeve, the outer chain plate and the pin are all interference fit, the roller, and the sleeve, and the sleeve and the pin are all clearance fits. When working, the inner and outer chain links can be relatively flexed, the sleeve can rotate freely around the pin shaft, and the roller is sleeved on the sleeve to reduce the wear between the chain and the sprocket.

In order to reduce the weight and equalize the strength of each section, the inner and outer chain plates are often made into an "8" shape. The parts of the chain are made of carbon steel or alloy steel and are usually heat-treated to achieve a certain strength and hardness.

Roller chain pitch

The center distance between two adjacent pins on the chain is called the chain pitch, which is represented by p. When the pitch increases, the size of each part in the chain increases accordingly, and the transmittable power increases accordingly. The chain pitch p is equal to the roller chain number multiplied by 25.4/16 (mm). For example, chain number 12, roller chain pitch p=12×25.4/16=19.05mm.

The type of the roller chain

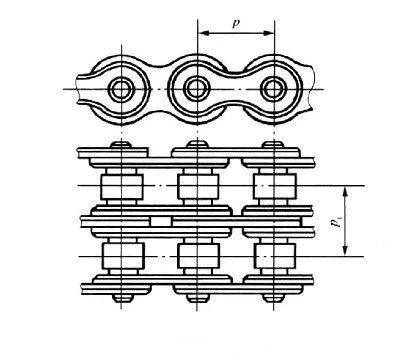

Roller chains can be made into single-row chains and multiple-row chains. When it is necessary to withstand large loads and transmit large power, multi-row chains can be used.

The multi-row chain is equivalent to several ordinary single-row chains connected with each other with long pins, and its carrying capacity is proportional to the number of rows, but the more rows there are, the more difficult it is to make the force of each row uniform, so the number of rows It should not be too much. Commonly used are double-row chains and three-row chains.

The connection method of the roller chain

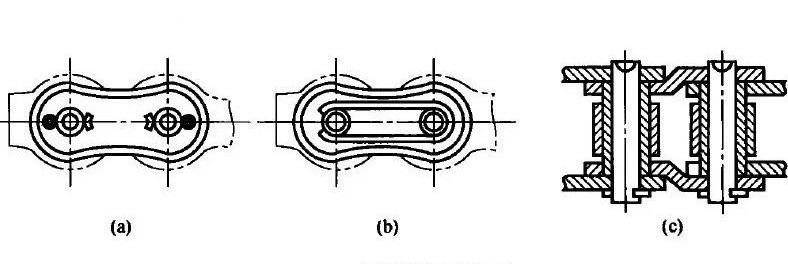

The length of the chain is expressed by the number of chain links. Generally, even-numbered chain links are used. The joints of the chain can use split pins or spring clips as shown in Figures (a) and (b). The former is used for large-pitch chains and the latter is used for Small pitch chains.

When the chain links are fixed by pieces, when the number is odd, transitional links should be used, as shown in figure (c). Since the bending chain plate of the transition link will generate additional bending moments when it is tensioned, it should generally be avoided as far as possible.

Applications of roller chain

Chain drives are widely used in various machinery in various industries such as agriculture, mining, metallurgy, petrochemical industry, and lifting and transportation. The power that the chain drive can transmit can reach 3600kW, usually used for power below 100kW; the chain speed can reach 30~40m/s, and the usual chain speed is below 15m/s; the transmission ratio can reach up to 15, generally less than 6, to 2~ 2.5 is appropriate.

Transmission characteristics of roller chain

Compared with belt transmission, there is no elastic sliding, can maintain an accurate average transmission ratio, and the transmission efficiency is higher. The chain does not require large tension, so the load on the shaft and bearing is small. The chain will not slip, the transmission is reliable, the overload capacity is strong, and it can work well under low speed and heavy load.

If you want to obtain knowledge and solutions about roller chains after reading the above, you can contact ZMIE CHAIN for professional advice.

As a professional quality chain supplier, being able to solve customer problems and provide customers with high-quality products is our ultimate goal. We have a professional production team and a strict quality inspection system, which can control the quality of our products in an all-round way. At the same time, we will also provide effective solutions according to the diverse needs of customers. If you want to buy our roller chain, please contact us immediately!