Alloy steel engineering steel bush chain | Bucket elevator chain | Steel detachable chain

Item specifics

- Material:

- 40Cr

- Heat Treatment:

- Through hardening

- Color:

- Natural

- Shipping:

- Support Sea freight.Express.Land freight.

- Application:

- Cement/Mining/Sugar/Wood

Review

Description

|

ZMIE

Chain NO. |

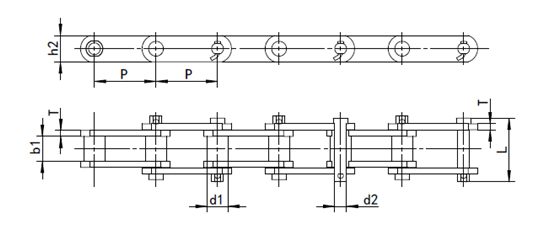

Pitch | Bush Diameter | Width Between Inner Plates | Pin Diameter |

Pin Length

|

Plate Dapth | Plate Thickness |

Ultimate Tensile Strength

|

Weight

Per Meter |

P | d1 max | bi min | d2 max |

L

max |

h2 max | T max |

Q

min |

q

|

|

mm | mm | mm | mm | mm | mm | mm | KN | kg/m | |

S188 | 66.27 | 22.40 | 26.90 | 12.70 | 68.60 | 28.40 | 6.40 | 102.00 | 5.60 |

S131 | 78.11 | 31.75 | 33.50 | 15.88 | 90.50 | 38.10 | 9.70 | 160.00 | 11.60 |

S102B | 101.60 | 25.40 | 54.10 | 15.88 | 111.30 | 38.10 | 9.70 | 160.00 | 10.40 |

S111 | 120.90 | 36.60 | 66.80 | 19.05 | 131.20 | 50.80 | 9.70 | 214.00 | 15.90 |

S110 | 152.40 | 32.00 | 54.10 | 15.88 | 111.30 | 38.10 | 9.70 | 160.00 | 9.80 |

|

S150

|

153.67 | 44.70 | 84.30 | 25.40 |

164.60

|

63.50 | 12.70 |

378.00

|

25.70

|

|

ZMIE Chain No.

|

Pitch

|

Bush Diameter

|

Width Betrween Inner Plates | Pin Diameter | Pin Length | Plate Depth |

Plate Thickness

|

Dimensions | Ultimate Tensile Strength | |||||

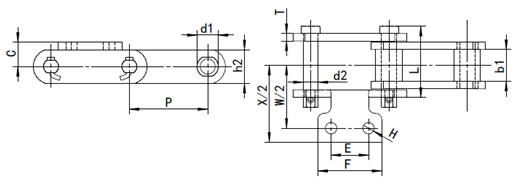

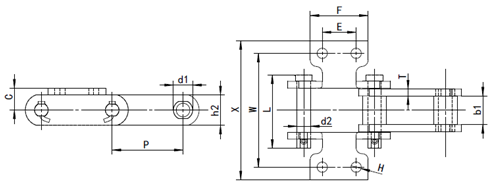

P | d1 max | b1 min | d2 max | L max | h2 max | T max | C | E | F | W | X | H | Q | |

|

mm

|

mm

|

mm | mm | mm | mm |

mm

|

mm | mm | mm | mm | mm | mm | KN | |

S188 | 66.27 | 22.40 | 26.90 | 12.70 | 68.60 | 28.40 | 6.40 | 20.6 | 31.70 | 54.10 | 106.40 | 130.00 | 9.60 | 102.00 |

S131 | 78.11 | 31.75 | 33.50 | 15.88 | 90.50 | 38.10 | 9.70 | 25.4 | 38.10 | 66.80 | 105.00 | 130.00 | 12.70 | 160.00 |

|

S102B

|

101.60

|

25.40

|

54.10 | 15.88 | 111.30 | 38.10 |

9.70

|

25.4 | 44.40 | 68.30 | 135.00 | 170.00 | 9.60 | 160.00 |

S110 | 152.40 | 32.00 | 54.10 | 15.88 | 111.30 | 38.10 | 9.70 | 25.4 | 44.40 | 73.10 | 135.00 | 170.00 | 9.60 | 160.00 |

ZMIE steel bush chain sometimes referred to as steel detachable chain (most commonly based on American Standards).

Generally interchangeable with cast combination chains and were developed as a superior replacement.

Being relatively light weight and durable these chains are well suited for bucket elevators driven by conventional toothed or plain rim traction wheels.

These bucket chains give excellent service in Cement and other dry abrasive applications.

Steel Chains keep elevators and conveyors operating in adverse conditions. Built to last in demanding applications, they are found in a variety of elevators and conveyor systems. Pins and knuckles are press fit into punched and shaved holes in the sidebars to reduce wear and to maintain dimensional accuracy. The robust construction makes Steel Bushed/Knuckle Chains ideal replacements for cast chains when conditions become too severe.

Pins are heat-treated alloy steel or case-hardened steel. Knuckles are case-hardened alloy steel. Sidebars are either heat-treated medium carbon or alloy steel. Straight and offset sidebar constructions are offered.

ENGINEERING CLASS DRIVE CHAIN Keep Your Operation Moving with alloy steel Chain is designed to exceed the listed ultimate strength ratings. These ratings are very significant. Chains with greater ultimate strength have higher actual yield and greater fatigue strength.